-

Home

-

About Elfack

-

Exhibitors

-

Activities

-

Plan your visit

-

For exhibitors

-

This is what electrical installers want to get out of the new mid-year event ELFACK: TA

Visitors’ wishes are crystal clear: give us more information, more knowledge! This became obvious when we asked the electricians themselves what they hope for at the premiere of ELFACK: TA, which is taking place at the Swedish Exhibition & Congress Centre in May 2022. Their answers testify to the growing and specific needs for new skills linked to the major energy transition.

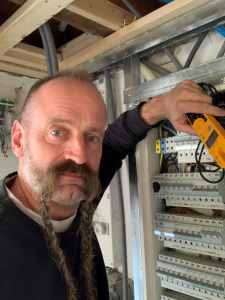

Jonas Kristiansson, EL-Finess Elinstallationer

What’s your view on knowledge requirements – which issues are most important to raise?

What’s your view on knowledge requirements – which issues are most important to raise?

Development is extremely fast right now, in every branch of technology. It is important for us to gain a greater understanding and knowledge of how all energy flows are connected: for example, the construction of systems for charging posts, solar cells, lighting control, RFID and common measurement. An enormous number of gadgets are being released onto the market. Why should a particular gadget exist and what does it really do? We need to know more, from the first to the last component.

What are the biggest challenges in the industry related to your business?

The supply of skills is extremely important. If we are to make the transition to a climate-smart society, with an ever-increasing degree of digitalisation, we must increase competence in all segments of the installation industry: electricity, security, passage, alarms, telecommunications and data. But we also need a better dialogue with customers, especially those responsible for purchasing, that’s to say, installers’ direct customers. Their knowledge of technological development must increase. I understand that it is not easy to keep up, but this often leads to unnecessarily incorrect orders in contract procurements. This in turn drives costs and affects the end customer. Everyone would benefit from an extended dialogue early in the process. It is always better to do the right thing from the beginning.

If you were free to choose: what would you most like to take part in, both on the exhibition floor and in the seminar programme?

What I would most like to see on the exhibition floor is live assembly. In other words, connected gadgets, devices and products, put into context. Which tells where, how and why. From an educational point of view, it is very rewarding to be able to see the function, to actually see what purpose the gadget serves. It also means that we as installers get a common message on how we should handle our sales: “Well, if you want a feature with improved communication, then you need this gadget.” In the seminar programme, I think it is important to provide some real-life current examples, with people who have both knowledge and experience of what is highlighted. In short, people who know what they’re talking about.

Martin Fernheden, Elektro-Centralen

What’s your view on knowledge requirements – which issues are most important to raise?

What’s your view on knowledge requirements – which issues are most important to raise?

Two things. I and my colleagues in construction want to know more about smart solutions for the home. There has been a rapid technological development that we’d like to gain greater insight into. I am also thinking of ergonomics and load issues. What aids are available for us? As electricians, we very often work above shoulder height; there are many twisting movements and pressure on the wrist. Many of us break down from strain prematurely. Maybe an expert in the field can give tips and advice?

What are the biggest challenges in the industry related to your business?

The biggest challenge I would say is the tight construction times. And all that entails in terms of stress and risks in the work environment. The goalposts are constantly moving on how far into a construction process the customer can make changes. And regardless of changes, the deadline must still be adhered to. The result is more work in less time. In today’s installation industry, there is fierce competition to get projects. We are seeing more and more foreign labour, which sometimes comes in with insufficient knowledge and works for lower wages. If foreign companies that pay low wages and don’t care about safety or the working environment become main contractors, it will also become a quality issue. There is a risk that work will not be carried out so well. Do customers dare to take that risk? I would like to hear more about this at ELFACK: TA. I would welcome views from the installation companies, but also from the rest of the business community, the unions and politicians.

If you were free to choose: what would you most like to take part in, both on the exhibition floor and in the seminar programme?

Smart solutions for the home! Examples of how you can easily integrate the control of lighting, sockets, sound, locks, alarms and everything else that exists today. And tips on innovative products and solutions to make work easier and smoother. In addition, I would like to hear more about what tool manufacturers think about the ergonomics aspect and the risk of occupational injuries when developing new products.

Marcus Arfwidsson, Arfwidssons Elektriska

What’s your view on knowledge requirements – which issues are most important to raise?

What’s your view on knowledge requirements – which issues are most important to raise?

I have an example, linked to the energy transition: recently we worked with a photovoltaic system that went down, that is, it did not charge because the solar cells were covered in snow. The battery pack charged from the system anyway and it was not easy to locate the source of the problem. It is an example that illustrates how we need to deepen our knowledge of renewable energy sources and various charging solutions. I regard this as very important.

What are the biggest challenges in the industry related to your business?

The lack of staff is a huge challenge. There is virtually no trained staff available. The level of knowledge of newly trained apprentices who come directly from high school is simply too low. Take an elementary thing like the construction of a central distribution system for a house. They have barely considered it in school and have no idea what it is. Basic knowledge, of the kind those of us who were educated 20-30 years ago brought with us, is lacking today. The effect will be that we employers may take on more responsibility during the apprenticeship year, which requires time and resources. To address the problem, I wish our industry could get a better insight into education. Let’s start a dialogue about the curricula and what we in the industry need. Today, unfortunately, the content of education does not correspond with the demand.

If you were free to choose: what would you most like to take part in, both on the exhibition floor and in the seminar programme?

Above all, I would like to see a focus on the transition to renewable energy. We can see how more and more people are switching to solar cells, battery storage and electric cars. The question is how we should solve the need for competence at the installer level. I myself am well versed, but that is because I have a personal interest in the issue. In addition, it is the case that people are becoming increasingly familiar from a consumer perspective. People read about and are updated on everything new that comes out, which places greater demands on us as installers. So at ELFACK:TA, I would welcome more targeted information for installers, primarily about charging solutions and green technology.

The new interim event ELFACK: TA will take place for the first time on 3–4 May 2022. It is aimed at the same visitor groups as regular editions of ELFACK, not least electrical installers, electricians and electrical and technical consultants. Read more about ELFACK:TA here »